The application and key points of riveting technology in instrument manufacturing in different structural instrument assembly

One, Introduction

Instrument manufacturing is an important link in modern industry, and riveting technology plays a crucial role in instrument manufacturing. Riveting technology achieves a firm whole by pressing metal materials together, thus forming a solid structure. In instrument manufacturing, the application of riveting technology is extensive, applicable not only to large-scale instrument equipment but also to small and precise instruments. This article will discuss the application and key points of riveting technology in different structural instrument assembly.

Two, Application of riveting technology in different structural instrument assembly

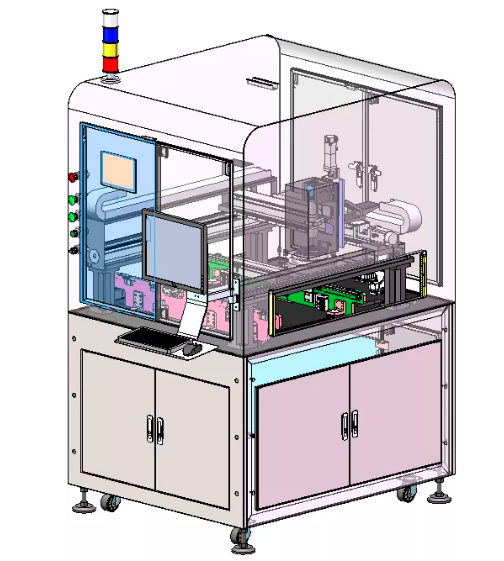

Assembly of large-scale instruments: Large-scale instruments are usually structurally complex and require the assembly of multiple components. The application of riveting technology in the assembly process of these components can ensure their firmness. For example, large-scale medical equipment, precision measuring instruments, and so on, whose internal structures are complex, require precise assembly of multiple components. At this time, riveting technology can ensure the connection strength of various components, improve the stability and reliability of the instrument.

Assembly of small and precise instruments: During the assembly of small and precise instruments, high-precision components are usually required. The application of riveting technology in the assembly process of these components can ensure their accuracy. For example, electronic instruments, optical instruments, and so on, whose internal structures are precise, require the assembly of multiple components. At this time, riveting technology can ensure the connection accuracy of various components, improve the accuracy and stability of the instrument.

Three, Key points of riveting technology in different structural instrument assembly

riveting technology in different structural instrument assembly

Selection of riveting technology: In different instrument assembly processes, different riveting technologies are selected. For example, for large-scale instruments, high-strength riveting technology is usually used to ensure their strength; for small and precise instruments, high-precision riveting technology is usually used to ensure their accuracy.

Selection of riveting materials: In different instrument assembly processes, different riveting materials are selected. For example, for large-scale instruments, high-strength metal materials are usually used to ensure their strength; for small and precise instruments, high-precision metal materials are usually used to ensure their accuracy.

used to ensure their strength; for small and precise instruments, high-precision metal materials are usually used to ensure their accuracy.

Control of riveting technology: In different instrument assembly processes, the parameters of riveting technology need to be controlled. For example, for large-scale instruments, it is necessary to control the force and speed of riveting to ensure their strength; for small and precise instruments, it is necessary to control the force and temperature of riveting to ensure their accuracy.

Four, Conclusion

In the field of instrument manufacturing, riveting technology is widely used, which not only ensures its strength but also its accuracy. In different instrument assembly processes, the selection of different riveting technologies, materials, and parameters can improve their stability and reliability. Therefore, understanding and mastering the application and key points of riveting technology in different structural instrument assembly is of great significance for improving the quality and efficiency of instrument manufacturing.